- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

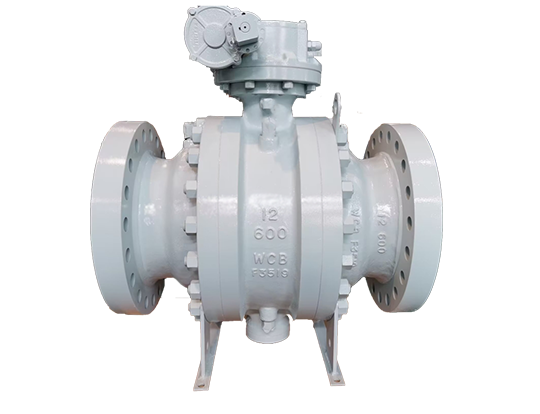

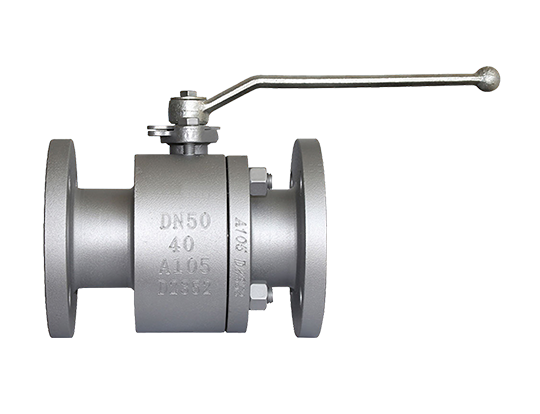

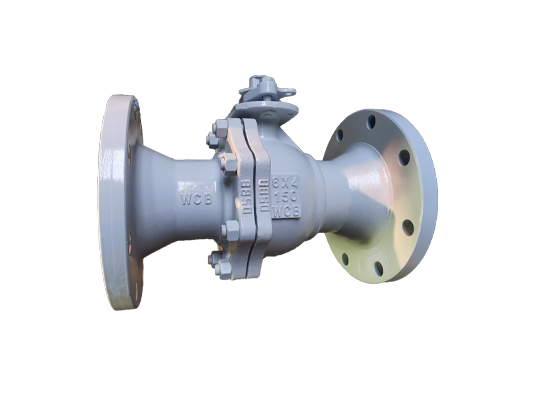

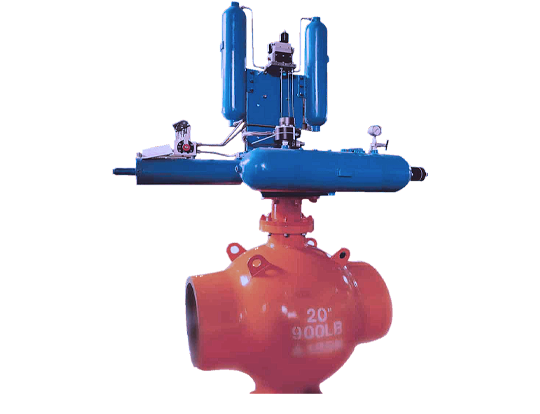

Large DN Size Oxygen Ball Valve

Send Inquiry

Product Introduction

LYV®️ large DN size oxygen ball valves is a special valve specially designed for oxygen pipe network, which is widely used in the pipe network of steel, metallurgy, petrochemical, chemical and other oxygen-using projects. In addition to the functions of ordinary valves, it also has its own characteristics such as good flame retardancy, good electrical conductivity, fast heat transfer, compact structure, oil resistance, safety and reliability. Strict oil prohibition measures are adopted during manufacturing, and all parts are subjected to strict degreasing treatment before installation. All diameter valves are equipped with conductive screw holes at the flange ends to prevent static electricity. The exposed parts of the valve have protective measures to prevent dust and oil pollution. With the valve seat of the metallurgical industry, the special oxygen ball valve and the special oxygen stop valve are widely used in steel, medicine, chemical and other industries.

Specifications

|

Design: API 6D、API608、BS 5351 |

Face to face: API6D、ASME16.10 |

|

Flange end: ASME B16.5、ASME B16.47 |

Butt-welding end: ASME B16.25 |

|

Test: API6D、API598 API6D、API598

|

Fire safe: API607、API6FA |

|

Size: 1/2”~36” |

Class: 150Lb~600Lb or PN6~PN100 |

|

Connection: Double flange |

Operation: Worm Gear、Pneumatic actuator |

|

Application: Iron and steel industry, metallurgy, petrochemical, chemical industry |

Body: HTB1、Aluminum bronze, ASME 1565 C86500、Brass, Monel, Stainless steel、SS304、SS316 etc. |

|

Ball: HTB1、ASME B564 NO400、Aluminum bronze, ASME 1565 C86500、Brass, Monel, Stainless steel、SS304、SS316 etc. |

Stem: ASTM B865 NO5500、C63200、F304、F316、SS321 |

|

Seat: PTFE、RPTFE、MONEL、ASME B564 NO400、C63200、F304、F316 |

|

Features

■ The design and manufacture of the oxygen ball valve meet the relevant requirements of GB16912.

■ Strict oil prohibition measures are adopted during manufacturing.

■ All parts are subjected to strict degreasing treatment before installation.

■ The exposed part of the valve stem should have protective measures to prevent contamination by dust and oil, and be marked with a "no oil" mark.

■ The flow channel surface of the inner cavity should be smooth and smooth.

■ The valve should be designed with obvious opening indication, and the handwheel should have the word "on-off" and an arrow on it.

■ Conductive screw holes should be provided on the end flange of the valve to make the bolt connection wire well grounded to prevent static electricity.

■ The lubrication of the support bearing should use fluorinated grease lubricant.

■ For valves with a nominal size of DN>150, the manufacturer recommends that a bypass device should be installed in the structure, and there should be an obvious flow direction mark.