- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

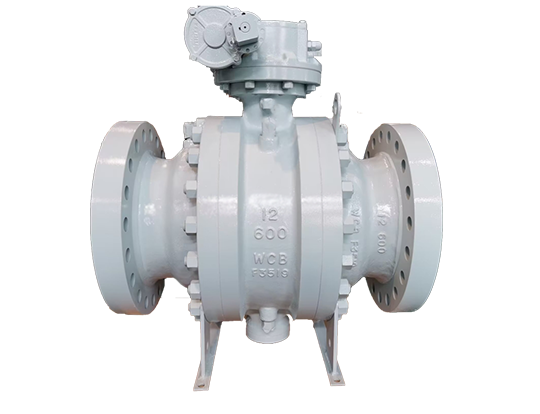

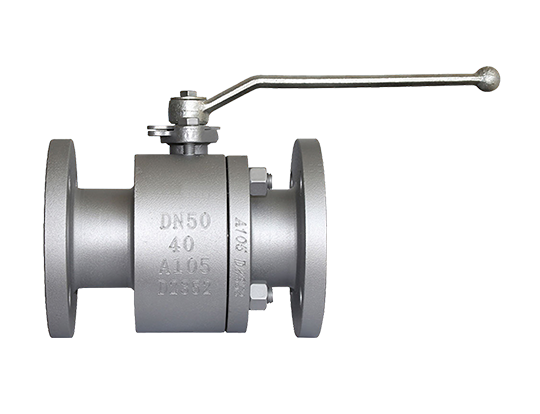

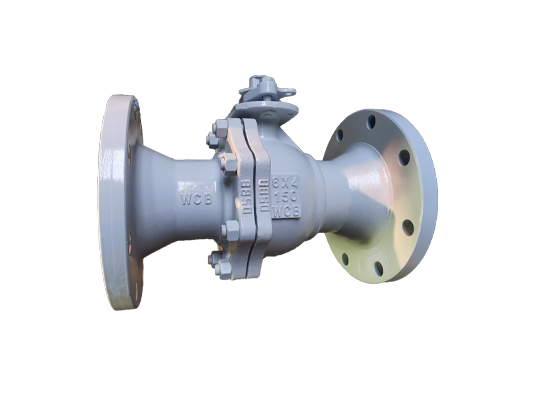

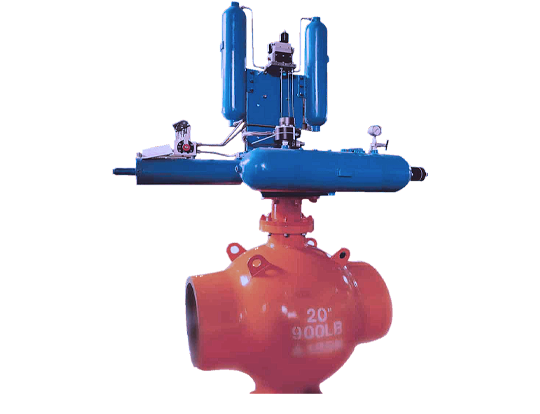

Forged Ball Valve

Send Inquiry

Product Introduction

LYV®️ Forged ball valve refers to a valve that uses the process of forged steel. In fact, the difference is in material, forged steel valves are often used in high temperature and high pressure conditions. There are commonly forged steel gate valves, forging steel globe valves, forged steel check valves, forged steel ball valves and so on. Forged valves are usually suitable for small size valves, with a range of 1/2” ~ 4″and pressure ranges of 150LB ~ 4500LB.

Specifications

|

Size Range: NPS 2”-48”; DN50-DN1000 |

Nominal Pressure: 150LB-2500LB; PN10-PN420 |

|

Temperature Range: -196℃~825℃(depends on design and material) |

End Connections: Flange; Butt-weld. |

|

Body Materials: ASTM A216 WCB/WCC; ASTM A352 LCB/LCC; ASTM A351 CF8/CF8M/CF3/CF3M/CF8C; ASTM A890 4A/5A/6A; ASTM A105; ASTM A182 F304/F316/F304L/F316L |

Ball Materials: ASTM A105N+ENP/A105N+TCC; ASTM A182 F304/F316/F304L/F316L; ASTM A182 F347/F51/F53/F55 |

|

Seat Materials: PTFE/RPTFE/FPM/PEEK; 304/316+STL/INCONEL |

Stem Materials: ASTM A182 F6A; ASTM A182 F304/F316/F304L/F316L; 17-4PH; ASTM A182 F51/F53/F55 |

|

Design & Manufacture Standard: API 6D |

Face-to-face Standard: ASME B16.10/ EN558-1 |

|

End Connection Standard: ASME B16.5/ ASME B16.25 |

Test & Inspection Standard: API 598 |

Features

●The hot forgings of forged valves improve recrystallization and grain refinement, thus contributing to the maximum possible strength and uniformization of the material.

●The contours of the valve body surrounded by grains to reduce metal fatigue.

●The forged valve body eliminates internal defects and harmonizes the metal structure for optimum performance.

●External pressure is the biggest problem for the impact between grains, but forging significantly reduces the occurrence of this problem and significantly increases the life of forged valves. Bi-directional tight shut-off

●The control of the dimensional consistency of the closed die forging of the forged steel valve has no defects caused by the displacement of the casting. Double block & bleed (DBB) / Double Isolation & Bleed (DIB)

●The ability of forging steel to fully meet the needs of most designs is the most important advantage. Low operating torque design

●Because of the above factors, forged valves have become indispensable products in the petroleum, chemical, pharmaceutical and high-demand power industries.

●Anti-blowout stem design