- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

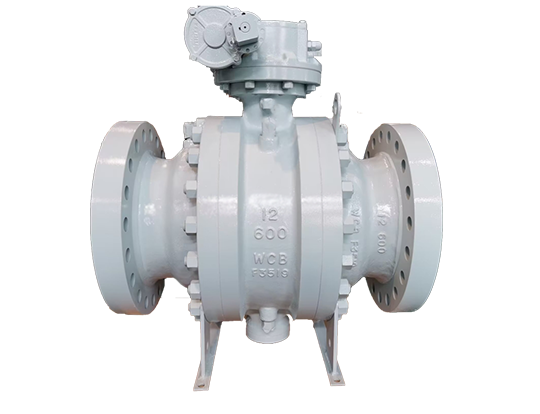

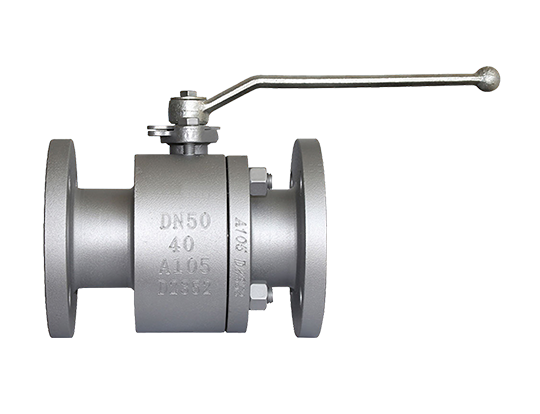

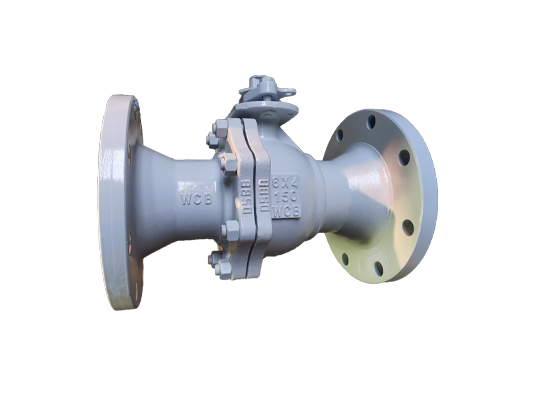

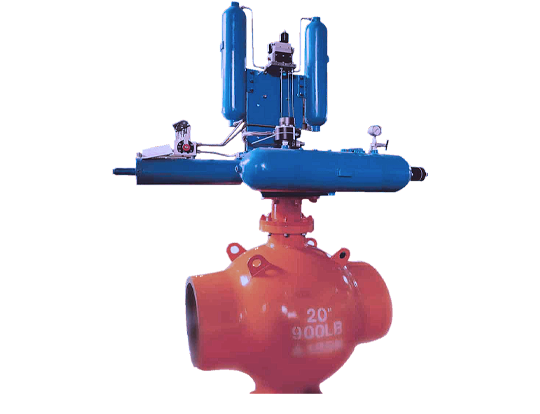

Cast Steel Trunnion Mounted Ball Valve

Send Inquiry

Product Introduction

LYV®️ cast steel trunnion mounted ball valve as a high-performance product that meets international standards like API-6A, API-6D, ASME-B16.34, ISO-17292 and more. LYV®️ cast steel trunnion mounted ball valve has obtained API-6FA fire certification, which prove product has capacity to use for various fire safe requested applications. LYV®️ as a manufacturer to produce cast steel trunnion mounted ball valve can manufacturing NPS 2” to NPS 48” trunnion mounted ball valve, maximum pressure rating can reach to 2500LB. Furthermore, LYV®️ has conditions and experience to produce low-temperature trunnion mounted ball valve. Contact our sales for more information.

Specifications

|

Size Range: NPS 2”-48”; DN50-DN1000 |

Nominal Pressure: 150LB-2500LB; PN10-PN420 |

|

Temperature Range: -196℃~825℃(depends on design and material) |

End Connections: Flange; Butt-weld. |

|

Body Materials: ASTM A216 WCB/WCC; ASTM A352 LCB/LCC; ASTM A351 CF8/CF8M/CF3/CF3M/CF8C; ASTM A890 4A/5A/6A; ASTM A105; ASTM A182 F304/F316/F304L/F316L |

Ball Materials: ASTM A105N+ENP/A105N+TCC; ASTM A182 F304/F316/F304L/F316L; ASTM A182 F347/F51/F53/F55 |

|

Seat Materials: PTFE/RPTFE/FPM/PEEK; 304/316+STL/INCONEL |

Stem Materials: ASTM A182 F6A; ASTM A182 F304/F316/F304L/F316L; 17-4PH; ASTM A182 F51/F53/F55 |

|

Design & Manufacture Standard: API 6D |

Face-to-face Standard: ASME B16.10/ EN558-1 |

|

End Connection Standard: ASME B16.5/ ASME B16.25 |

Test & Inspection Standard: API 598 |

Features

■ Soft or metal seat available

■ Solid ball

■ RF,RTJ,BW Connection face

■ Two- or three- piece body

■ Bi-directional tight shut-off

■ Zero leakage

■ Double block & bleed (DBB) / Double Isolation & Bleed (DIB)

■ Fire-safe protection.

■ Low operating torque design

■ Anti-blowout stem design